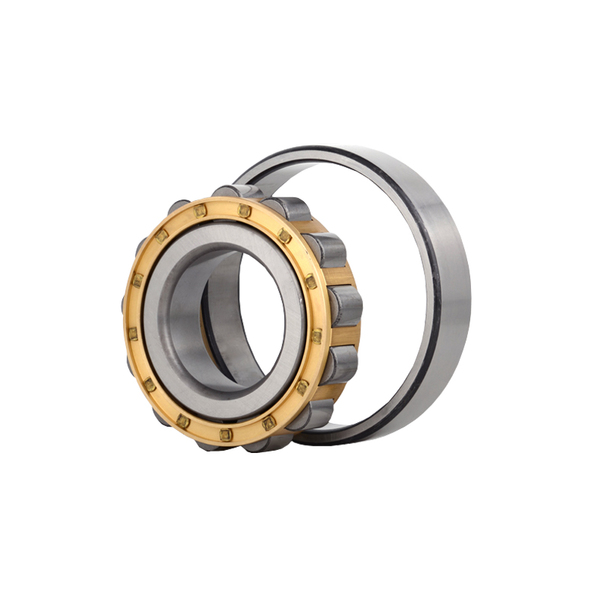

What is needle roller bearing

Needle roller bearings are roller bearings with cylindrical roller, relative to its diameter, the roller is thin and long.

This type of roller is called a needle roller.

Despite having a small section, the bearing still has a high load bearing capacity.

Classification of needle roller bearings

Open type stamped outer ring needle roller bearings, closed stamped outer ring needle roller bearings, needle roller bearings with inner ring and without inner ring needle roller bearings/needle roller bearings without inner ring and cage, full needle roller bearings with and without cage.

The role of needle roller bearings

Needle roller bearings are equipped with thin and long rollers, so the radial structure is compact, the inside diameter size and load capacity are the same as other types of bearings, the outer diameter is the smallest, especially suitable for the radial installation size of the limited supporting structure.

Needle roller bearings according to the use of different occasions, processing accuracy and surface quality should be combined with bearing ring, purpose.

Effect of lubrication on needle roller bearings

Whether the lubrication is proper is of great help to the use of combined needle roller bearings. The grease lubricated with grease has both sealing effect. The sealing structure and lubrication equipment are simple, and the grease is easy to supplement.

1. The cooling effect of oil lubrication is strong, and it can take away dirt and moisture from the combined needle roller bearing.

Combination needle roller bearings with oil lubrication lubrication methods include pressure oil supply lubrication, oil injection lubrication, oil mist lubrication and oil and gas lubrication.

2. Pressure oil supply lubrication is the most effective lubrication method of combined needle roller bearing under conventional speed.

3. Oil injection lubrication is the lubricating oil with a certain pressure through the injection nozzle installed on the side of the combined needle roller bearing into the bearing interior to stop lubrication, commonly used in high-speed combined needle roller bearings, or pressure oil supply lubrication can not meet the cooling begged place.

4. Spray lubrication is to spray the monotonous compressed air containing oil mist into the interior of the combined needle roller bearing to stop lubrication. The amount of oil is less, and the cooling effect is very strong due to the effect of air.

The price of needle roller bearings

The price of needle roller bearings is affected by many factors such as market, material and quotation. If you want to know the specific price of needle roller bearing,please contact us to make enquiries.

Supplier of needle roller bearings:BMB Bearings

BMB Bearings is the complete one-stop supplier of OEMs and wholesalers purchasing high-precision, miniature ball bearings, industrial ball bearing related products, as well as related professional services, including world-class engineering and design. If you have any need, please feel free to contact us .